Gaining Traction: How to Choose the Right CTL Tracks

Posted by Mackenzi Griffin on 21st Aug 2023

In the dynamic realms of construction, agriculture, and other industries that involve terrain manipulation, the skid steer has firmly planted its presence as an indispensable tool. This compact loader, with its modest size, is a powerhouse of versatility, equipped to push, pull, lift, and load materials. If you have ever operated a skid steer, it's evident that its adaptability is not just a result of its design, but also its undercarriage. Herein lies the profound connection between a skid steer and its CTLTracks.

MWE (Midwest Equipment) tracks are expertly crafted and tailored specifically for these loaders. Tracks are an integral component that redefines your machine's capabilities, amplifying its prowess and enabling it to traverse and operate seamlessly across a variety of terrains, from muddy construction sites to uneven agricultural lands.

But not all tracks are created equal. The MWE range offers a diverse selection of track patterns, each meticulously designed with a distinct application in mind. We’ll dissect the nuances of each type, and provide some insights into their unique roles, advantages, and the terrains they are best suited for.

C-Lug Pattern

Sculpted to handle the vast spectrum of terrains – from rocky outcrops to slippery slopes – its distinct C-lug configuration provides a tough grip, ensuring that each step is firmly grounded, significantly minimizing the chances of unexpected slips or skids.The pattern's inherent versatility marks it as a true all-rounder. Whether navigating the rugged demands of construction sites, tending to the nuanced challenges of landscaping, or performing light agricultural duties in the ever-changing outdoors, this design rises to the occasion. It's not just about getting the job done; it's about doing so with a level of assurance and safety, making it an indispensable choice for a broad range of general tasks.

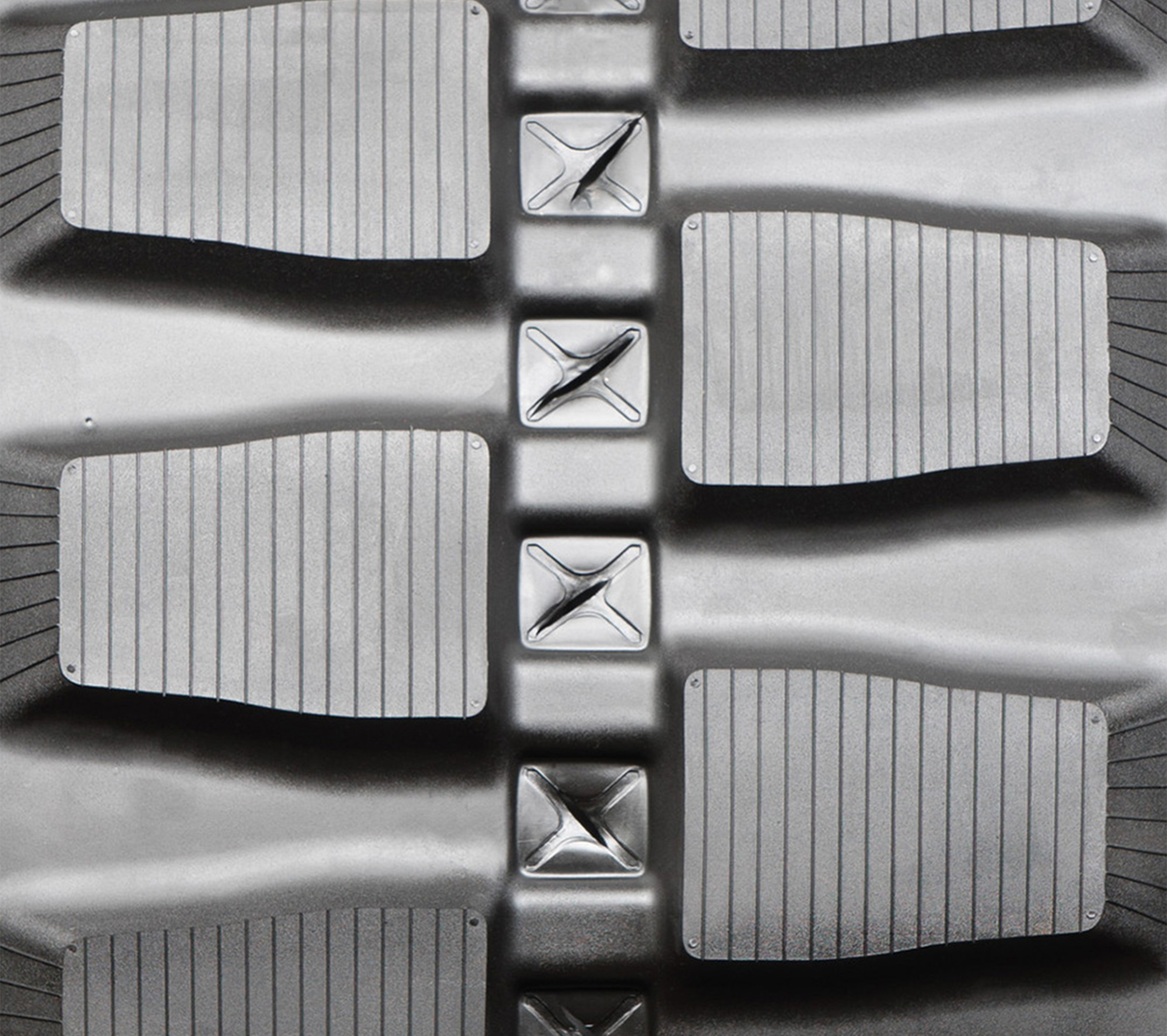

Block Pattern

Crafted specifically for soft terrains such as thick mud, freshly fallen snow, or shifting sand, the track's intricate block pattern boasts an expansive surface area. This enhanced design significantly diminishes the likelihood of the vehicle becoming mired or sinking into the soft ground beneath it. Through the thoughtful distribution of the block pattern, the design expertly disperses the skid steer's weight over a broader expanse, to guarantee reliable and consistent traction even over the most demanding terrains. Whether it's for meticulous beach cleanup after a storm, efficiently removing blankets of snow from pathways, or maneuvering through waterlogged, boggy fields, this track is designed with adaptability in mind.

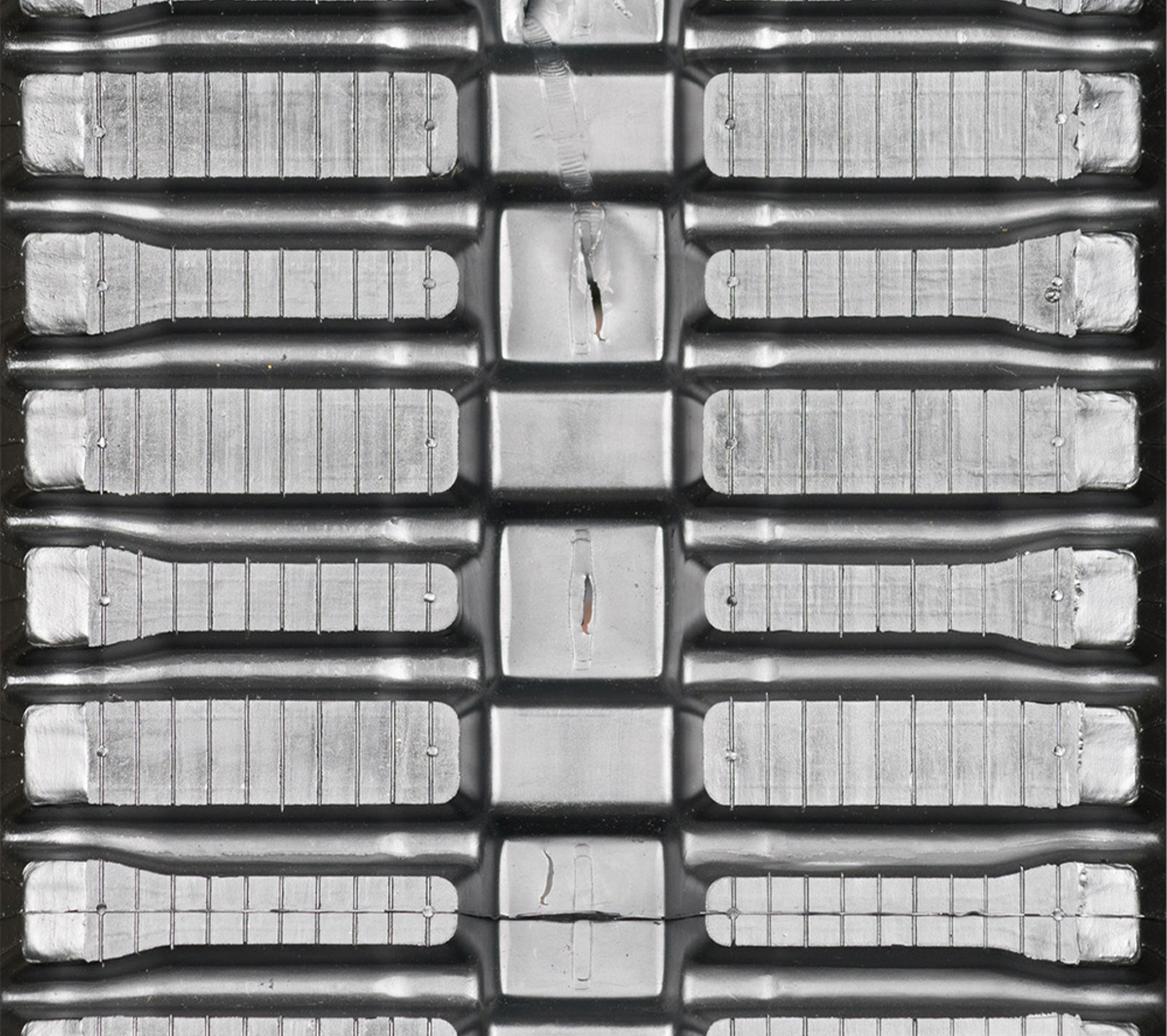

Multi-Bar Pattern

Ideally suited for the demands of agricultural terrain and soft ground conditions, this innovative design seamlessly blends the advantages of both bar and block patterns. Crafted meticulously, the track features an array of bars that span its circumference. These bars, strategically placed, provide an elevated grip that ensures skid steers have a superior foothold, particularly when navigating through farmlands laden with organic residue or terrains riddled with debris. In the realm of farming, the challenges posed by soft soil cannot be underestimated. Whether it's the squelchy unpredictability of mud or the often-treacherous mixture of wet soil interspersed with rocks, branches, and other debris, a reliable grip is essential. The bars dig deep into the earth, while the block patterns act as cushions, providing both support and balance. This combination not only maximizes performance but also ensures safety in unreliable environments.

Zig-Zag Pattern

When working on hard surfaces or navigating rugged, rocky terrains, the zig-zag pattern’s intricate design, resembling a series of interconnected chevrons, ensures that the skid steer remains grounded, maintaining optimum grip even when the surface beneath it is unpredictable or unforgiving.

But the benefits don't stop at mere grip. The interlocking zig-zag design serves a dual purpose. While it guarantees consistent traction, it also plays a crucial role in minimizing wear and tear on the tracks. Each zig and zag works collaboratively, distributing pressure and reducing the potential for premature erosion.

Such design considerations become critical in specialized applications, whether it’s mining operations, extracting resources from a quarry, or simply maneuvering on surfaces that are as hard as concrete, the zig-zag pattern stands out for its engineering foresight. It ensures not just the efficacy of the skid steer's operation but also its longevity in demanding industries.

Your skid steer's adaptability is amplified by MWE tracks. Understanding the distinct capabilities and applications of each pattern is not just beneficial but imperative. This knowledge ensures operators extract the utmost performance from their machines, guaranteeing optimal outcomes regardless of the terrain or task at hand. In the realm of heavy machinery, the skid steer's future is as much about its tracks as its engine or design. Choose wisely and tread confidently.